Cocoa powder feels like one of those ingredients we all know… until someone asks how it’s actually made.

We bake with it.

We stir it into hot chocolate.

We rely on it for deep, chocolate flavor.

But the journey from a tropical cacao tree to that fine brown powder in your pantry is surprisingly detailed—and honestly fascinating.

This complete guide walks you through how cocoa powder is made, step by step, in plain language. No food science degree required. Just real explanation, real examples, and a better understanding of what you’re actually using in your kitchen.

What Exactly Is Cocoa Powder?

Cocoa powder is made from cacao beans, the seeds found inside cacao pods. These beans go through multiple stages—fermentation, drying, roasting, grinding, and pressing—before they become cocoa powder.

What surprises many people is this:

Cocoa powder is not ground chocolate.

It’s actually what’s left after most of the cocoa butter is removed from chocolate liquor. That detail matters, because it explains cocoa powder’s intense flavor and dry texture.

Where Cocoa Beans Come From

Cacao trees grow near the equator, where the climate is warm and humid.

Most of the world’s cacao comes from:

- Ivory Coast

- Ghana

- Ecuador

- Indonesia

Farmers harvest cacao pods by hand. Each pod contains 20–50 beans, surrounded by a sweet, white pulp.

This is where the real transformation begins.

Step 1: Harvesting the Cacao Pods

Cacao pods don’t ripen all at once. Farmers inspect trees carefully and cut ripe pods using machetes or long-handled knives.

Inside each pod:

- Raw cacao beans (purple or pale)

- Sweet, sticky pulp

At this stage, the beans don’t taste like chocolate at all.

They’re bitter. Sharp. Almost vegetal.

Step 2: Fermentation – Where Flavor Is Born

Fermentation is the most important step in cocoa powder production.

What Happens During Fermentation?

- Beans are piled into boxes or wrapped in banana leaves

- Natural yeasts and bacteria break down the pulp

- Heat builds naturally

- Beans darken in color

This process lasts 5 to 7 days.

Without fermentation:

- Cocoa would taste flat

- Chocolate flavors would never develop

According to National Institutes of Health, fermentation is what creates the flavor precursors that later turn into chocolate aromas during roasting.

Step 3: Drying the Beans

After fermentation, beans are spread out to dry—usually in the sun.

Drying:

- Reduces moisture

- Prevents mold

- Stabilizes flavor

This step can take one to two weeks, depending on weather.

Once dried, beans are packed and shipped to chocolate and cocoa processors around the world.

Step 4: Roasting – Deepening the Chocolate Flavor

Roasting is where chocolate aroma finally shows up.

Processors roast beans at carefully controlled temperatures. The exact time and heat depend on:

- Bean origin

- Desired flavor profile

- Final product (cocoa powder vs chocolate)

Roasting:

- Deepens flavor

- Reduces acidity

- Makes shells easier to remove

This is similar to coffee roasting—small changes make a big difference.

Step 5: Cracking and Winnowing

Once roasted, beans are cracked open.

This separates:

- Cocoa nibs (the valuable part)

- Shells (discarded or repurposed)

Cocoa nibs are pure, roasted cacao. They’re crunchy, bitter, and intensely chocolatey.

At this point, nibs can be sold as-is—or processed further.

Step 6: Grinding into Chocolate Liquor

Cocoa nibs are ground into a thick paste called chocolate liquor (also known as cocoa mass).

Despite the name, there’s no alcohol involved.

Grinding releases cocoa butter, turning dry nibs into a smooth, flowing paste.

Chocolate liquor contains:

- Cocoa solids

- Cocoa butter

This is the base for both:

- Chocolate bars

- Cocoa powder

Step 7: Pressing Out the Cocoa Butter

Here’s where cocoa powder is born.

Chocolate liquor is placed into hydraulic presses that squeeze out most of the cocoa butter.

What remains:

- Solid cocoa “cake”

This cake is:

- Dry

- Dense

- Packed with chocolate flavor

The removed cocoa butter goes on to make chocolate bars, cosmetics, and more.

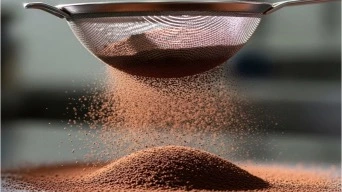

Step 8: Grinding into Cocoa Powder

The cocoa cake is crushed and ground into a fine powder.

This powder is sifted for consistency and packaged.

Depending on processing choices, it becomes:

- Natural cocoa powder

- Dutch-processed cocoa powder

Natural vs Dutch-Processed Cocoa Powder

Natural Cocoa Powder

- Lighter in color

- Sharp, acidic flavor

- Reacts with baking soda

Dutch-Processed Cocoa Powder

- Darker color

- Milder, smoother taste

- Neutral acidity

Dutch processing involves washing cocoa with an alkaline solution to reduce acidity.

Fat Content: Why It Matters

Not all cocoa powder is the same.

Cocoa powder typically contains:

- 10–12% fat (standard)

- 20–24% fat (rich, premium)

Higher fat cocoa:

- Tastes richer

- Mixes smoother

- Costs more

This is why some cocoa powders make better hot chocolate, while others shine in baking.

Is Cocoa Powder Healthy?

Cocoa powder is surprisingly nutrient-dense.

It contains:

- Antioxidants (flavanols)

- Iron

- Magnesium

- Fiber

According to Harvard T.H. Chan School of Public Health, minimally processed cocoa retains beneficial compounds—especially when unsweetened.

Of course, benefits depend on how much sugar you add. Read our article on Health Benefits of Cocoa Powder.

How Cocoa Powder Is Used Around the World

Cocoa powder isn’t just for desserts.

It’s used in:

- Hot chocolate

- Baking

- Savory sauces (like mole)

- Drinks and smoothies

Different cultures emphasize different uses, which ChocoTalk.com explores in its global cocoa traditions feature.

Short FAQ: How Cocoa Powder Is Made

Is cocoa powder the same as cacao powder?

Not exactly. Cacao powder is usually raw and less processed.

Does cocoa powder contain caffeine?

Yes, but much less than coffee.

Why is some cocoa powder darker?

Dutch processing changes color and acidity.

Can cocoa powder go bad?

It lasts years if kept dry and airtight.

Final Thoughts: From Bean to Powder

Cocoa powder may look simple, but it carries a long, careful journey inside every spoonful. From tropical farms to fermentation boxes, from roasting drums to hydraulic presses, each step shapes the flavor we love.

Understanding how cocoa powder is made doesn’t just make you smarter in the kitchen—it helps you choose better products, bake with confidence, and appreciate chocolate on a deeper level.

If you love learning the why behind chocolate, you’ll find plenty more thoughtful guides waiting for you on ChocoTalk.com—where every bite truly tells a story.